Troubleshooting Common Issues with Grit Traps: How to Ensure Optimal Performance

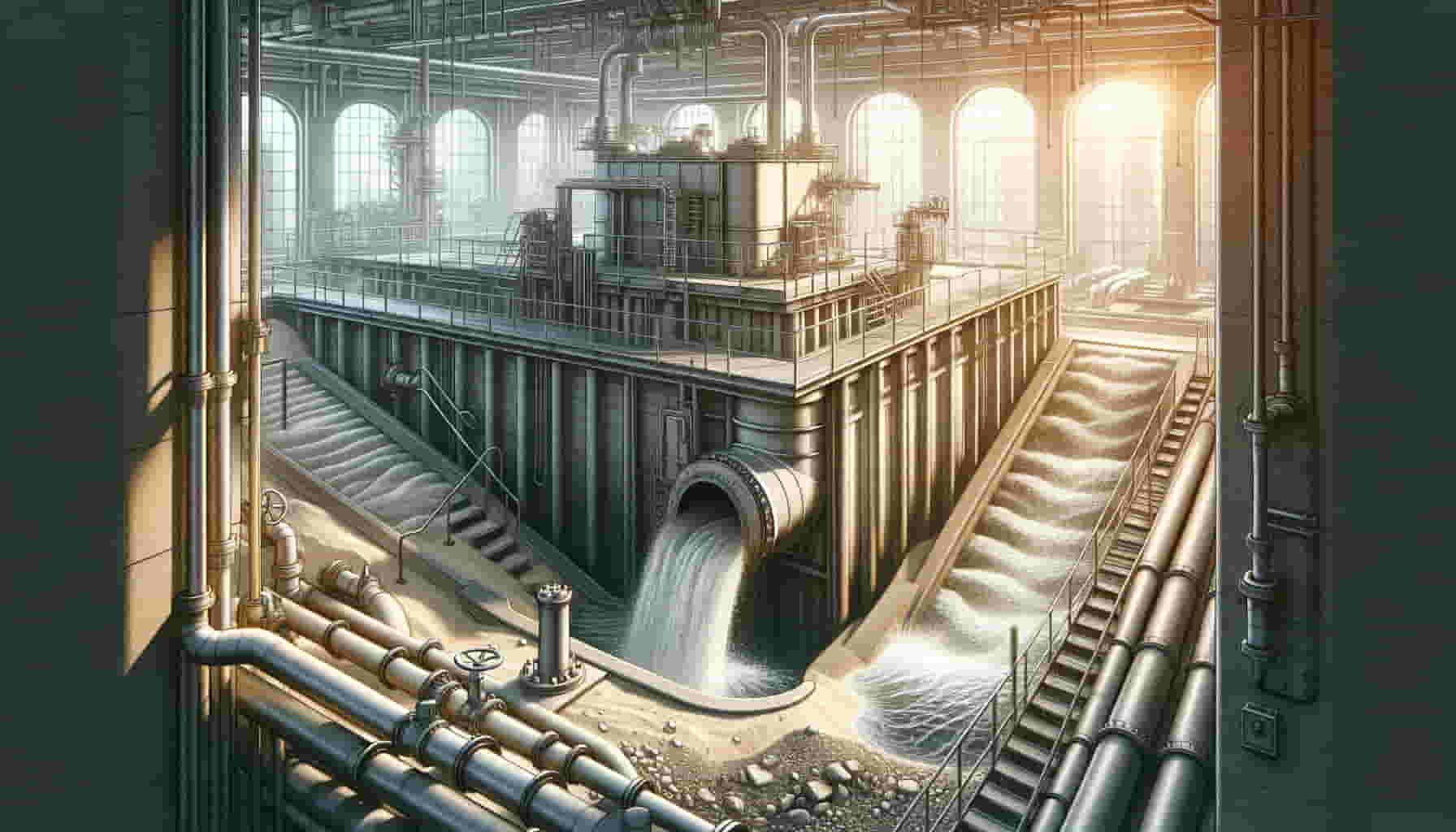

Grit traps are essential components of commercial kitchen drainage systems, designed to capture and retain solid particles, grease, and other contaminants before they enter the main sewage system. These devices play a crucial role in maintaining a clean and efficient kitchen operation, preventing costly blockages, and protecting the environment from harmful pollutants. However, like any mechanical system, grit traps can encounter various issues that may affect their performance. In this article, we’ll explore some of the most common problems associated with grit traps and provide practical solutions to ensure their optimal performance.

Understanding Grit Trap Basics:

Before diving into troubleshooting, it’s essential to understand the fundamental working principles of grit traps. These devices consist of a concrete or plastic tank with multiple chambers, each designed to trap different types of waste. The first chamber, known as the sediment trap, captures heavy solids, such as sand, soil, and other debris. The second chamber, called the grease trap, retains fats, oils, and grease (FOG) by allowing them to cool and solidify. Finally, the third chamber, or effluent trough, collects any remaining contaminants before the wastewater exits the system.

Common Grit Trap Issues and Solutions:

Clogged Inlets and Outlets:

One of the most common grit trap problems is clogged inlets and outlets, which can significantly reduce the flow of water and lead to backups or overflows. Clogs can occur due to the accumulation of food debris, grease buildup, or improper maintenance.

Solution: Regular inspection and cleaning are essential to prevent clogs. Establish a cleaning schedule based on the volume of use and follow the manufacturer’s recommendations for safe and effective cleaning methods. Additionally, consider installing strainers or screens to catch larger particles before they enter the grit trap.

Odor Problems:

Unpleasant odors emanating from grit traps can be a major nuisance and a sign of deeper underlying issues. Odors can result from the buildup of organic matter, inadequate maintenance, or a lack of proper ventilation.

Solution: Address odor problems by ensuring regular cleaning and proper ventilation. Install a vent pipe to allow air circulation and prevent the accumulation of foul-smelling gases. Consider using deodorizing agents or bacterial treatments designed specifically for grit traps to help break down organic matter and neutralize odors.

Grease Buildup:

Grease buildup is a common issue that can significantly reduce the efficiency of grit traps. Over time, grease can solidify and accumulate in the trap, leading to clogs, backups, and decreased flow.

Solution: Implement a comprehensive grease management program that includes regular cleaning, the use of biological or enzymatic grease-degrading agents, and employee training on proper grease disposal practices. Ensure that all kitchen staff understands the importance of minimizing grease discharge and the proper techniques for scraping plates and disposing of grease before washing dishes.

Corrosion and Structural Damage:

Grit traps are subjected to harsh conditions, including exposure to acidic and alkaline substances, which can lead to corrosion and structural damage over time. Cracks, holes, or deterioration of the trap’s material can compromise its effectiveness and pose environmental risks.

Solution: Conduct regular inspections to identify signs of corrosion or structural damage. If issues are detected, consider replacing the affected components or the entire grit trap. Choose corrosion-resistant materials, such as fiberglass or high-density polyethylene (HDPE), for new installations or replacements.

Overflows and Backups:

Overflows and backups can occur when the grit trap becomes overwhelmed by the volume of wastewater, solids, or grease. These issues can lead to flooding, unsanitary conditions, and potential health hazards.

Solution: Ensure that the grit trap is sized appropriately for the volume of wastewater generated by your kitchen. Consider upgrading to a larger or more efficient model if necessary. Additionally, implement a regular cleaning schedule to prevent excessive buildup of solids and grease, which can contribute to overflows and backups.

Ensuring Optimal Grit Trap Performance:

Maintaining the optimal performance of grit traps requires a comprehensive approach that involves regular cleaning, proper maintenance, and employee education. Consider the following best practices:

Develop a Cleaning Schedule: Establish a cleaning schedule based on the volume of use and the manufacturer’s recommendations. Regular cleaning is essential to prevent clogs, odors, and buildup.

Train Employees: Educate kitchen staff on the importance of proper grease disposal, scraping plates, and minimizing the discharge of solids into the drainage system. Proper employee training can significantly reduce the burden on grit traps and extend their lifespan.

Conduct Regular Inspections: Perform regular inspections to identify any issues, such as clogs, structural damage, or excessive buildup of solids or grease. Early detection can prevent more significant problems from developing.

Hire Professional Services: Consider working with professional grit trap cleaning and maintenance companies to ensure that your traps are serviced correctly and efficiently. These companies have the expertise and equipment to handle even the most challenging grit trap issues.

Follow Regulations: Familiarize yourself with local regulations and guidelines regarding grit trap maintenance and disposal. Ensure that your grit trap system complies with all relevant environmental and health codes to avoid fines or legal issues.

Conclusion:

Grit traps play a vital role in protecting the environment and maintaining efficient kitchen operations. By understanding common issues and implementing practical solutions, you can ensure that your grit traps perform optimally, preventing costly blockages, backups, and potential environmental hazards. Regular maintenance, employee training, and professional services are key to keeping your grit traps in top condition and ensuring compliance with all applicable regulations. By addressing problems promptly and following best practices, you can prolong the lifespan of your grit traps and maintain a clean, safe, and efficient kitchen environment.